This was part of the final year capstone at McMaster University. In the department of ECE, we are allowed to do virtually to anything as long as it's approved. Typically the only requirements is that there is a hardware component and that it's realistic to complete. This must be completed in groups of at least 2. The project that our group decided to do was create an automated badminton shuttle launcher that could be either cheap or easily built and open source. The idea was originally mine, which was inspired by my passion to improve at the sport but could never afford proper training. We wanted to develop the product using items that are widely available so that it could be recreated by others. The goal was to eventually have a repository of different "builds" of the same or similar device. These would use different parts, fill different niches or even supersede the original. These different builds would be contributed by other people interested in the product. People can then choose from these builds and look through a list of parts and guides on how to build one themselves. Group Members: Allan Hieng, Nicholas Amorim, Dyllan Appelbohm, Mackenzie Wiens Winner of McMaster ECE Expo 2018/2019 - Best Electrical Design

As an avid badminton player, I had always looked for ways to improve. Often the best and most recommended way would be to get a coach. However, in the city I grew up in there was quite literally only 1 coach unlike cities where the sport is more popular. Nowadays, it's much better, but the same thing still remains that acts as a barrier for new players: cost. Badminton can be very expensive, especially if you get training. I won't get into detail what a coach can offer, because BOSS was not designed to replace one. Badminton requires 2 people to properly practice, the quality of the practice is determined by the skill of the players and how consistent they can "feed" shots to the person practicing. BOSS looks to fill in this gap by offering a DIY open source alternative.

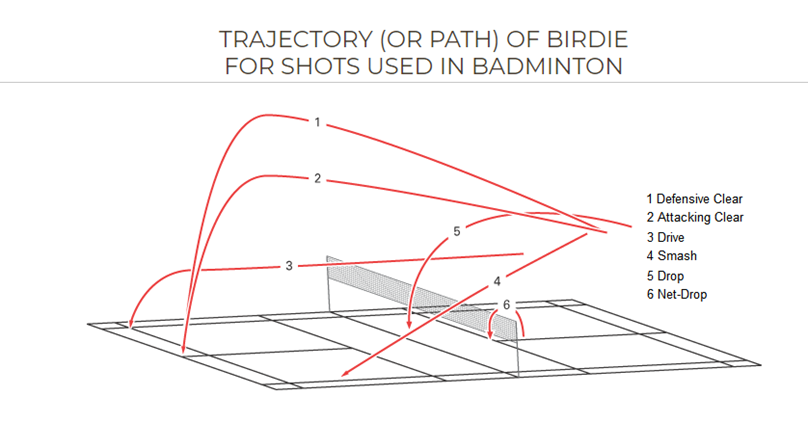

When feeding shuttles to a player, there's generally only a few shots that are used for practice. These general shots can be seen below on figure 1. There's much more variation of each shot, but these are good enough for practice as it's more about what shot is played after and how the player reacts. A good feeder will hit the shots to the same locations with a very good degree of consistency and while varying shots based on the drill. For our purposes we will prefer to be able to hit a few types of shots at a high degree of consistency as opposed to hitting all the shots with a lower degree of consistency.

Figure 1. The 6 basic flight paths of shuttles

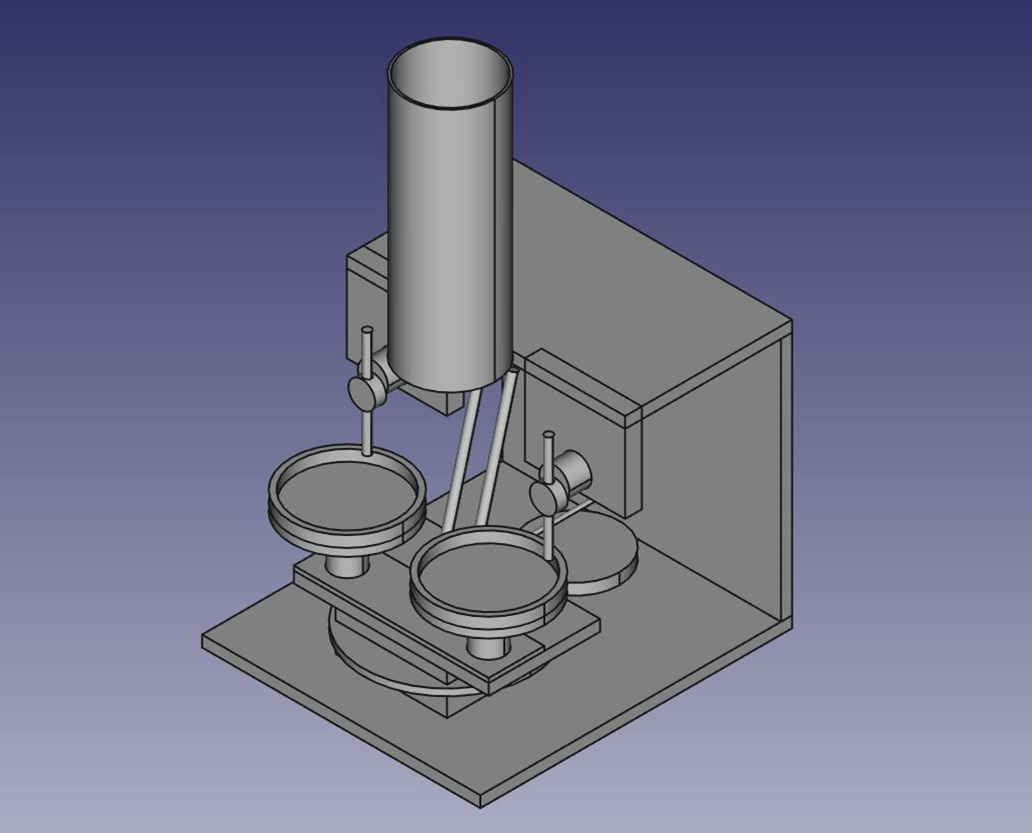

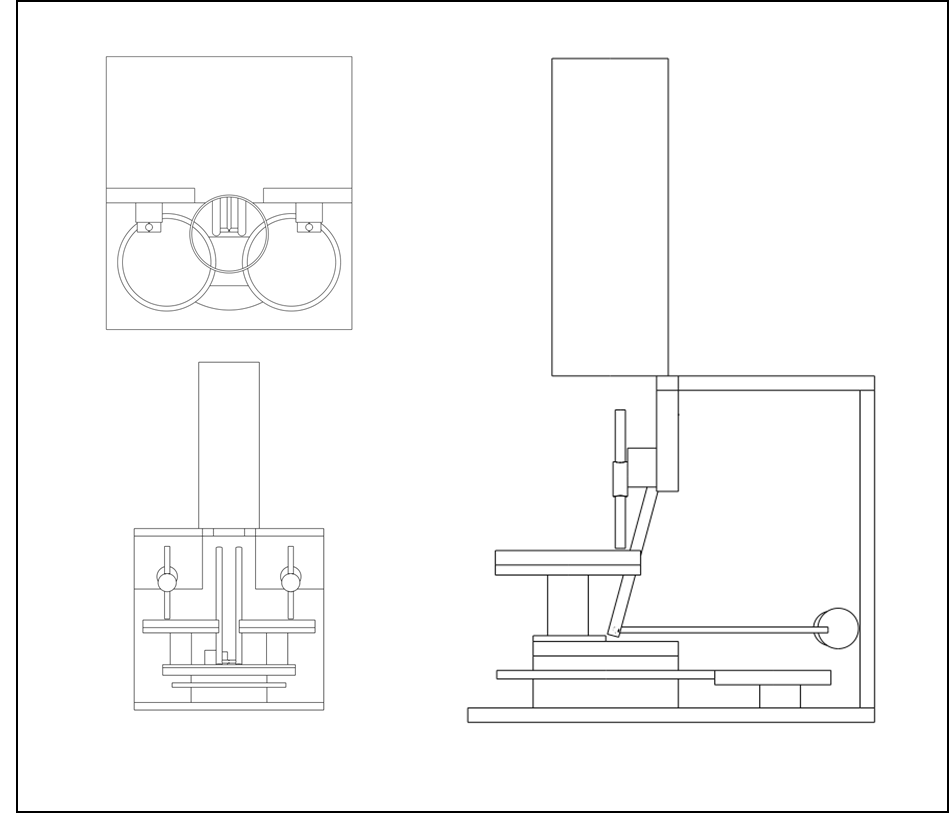

This was likely the hardest part of the project. There are many ways to hit the shuttle, but we had to use a way that was feasible and would not destroy feather shuttles. There was also the topic of how birds would be loaded. For our purposes we decided to stick to nylon shuttles since they're more durable and can handle the abuse better than feather ones. The goal would be to use feather ones eventually. This is because every serious badminton tournament would use feather shuttles, and presumably only serious players would be interested in this product. The initial question is how to launch the bird. Many things were considered from using a robotic arm that would swing a racket to using compressed air. While exploring online, we found some other products that aimed to do the same thing. Some used brushless motors, and they seemed to have higher output when compared to say a brushed motor. Output here refers to torque, as I was very skeptical if a brushed motor could launch a shuttle to the far end of the court. The idea was that wheels would be connected to the brushless motor and the cork of the shuttle would make contact and thus be launched. For our initial tests we used the wheels from a toy stroller, as it was really cheap. We didn't have any reference levels, but we knew that the size of the wheel would be a factor. As seen in video 1, the results were actually better than anticipated. Not long after, we decided to 3D print some wheels for better testing. The next part was how to deliver the shuttle to the launcher. We knew that the shuttles would be stored in a tube that would be slightly larger than a regular badminton tube. This is so the birds would keep falling when the next one is pulled, and a flexible mesh would be used to stop them all from falling in at once. The shuttles would then get caught on this mesh which with a bit of pull would release the bird. We decided to use some "rails" that would guide the shuttle into the wheels. Stepper motors were then used to pull the shuttle down. This is done by attached "arms" to the stepper motors, which would turn and exert a very small pull. Stepper motors were used largely because they were cheap and we had used them in our control systems class. A lazy susan bearing was chosen to help the device aim the sides. This was largely chosen by my group members since they've had previous experience using it. The method chosen was to have another stepper motor control a gear that would be connected to the lazy susan bearing. Originally we tried it without a bearing, but it caused the whole turning portion to become more rigid. The bearing was more smooth and offered more consistency. Originally, we had wanted the device to tilt so that we could control the angle. After some consideration, we decided against it. Mostly due to time, and that the value of being able to perform shots left/right is of more value. The tripod this was mounted on could also be tilted up or down. To us, this was "good enough" half measure. The last important part of our design was how we were going to control the horizontal distance. We did have control over the motors, but there issues which I will discuss later. Something we noticed during our testing was how much contact the cork of the shuttle had with the wheels would and how it would affect the distance it travelled. This was likely because more contact meant more transfer of force. We then used another stepper motor that would move the "launching guide" closer or further. This would be how we would control distance.

Figure 2. Isometric view of the final prototype of BOSS

Figure 3. Drawing view of the final prototype of BOSS

Assigned to: Dyllan Appelbohm Nicholas Amorim Allan Hieng

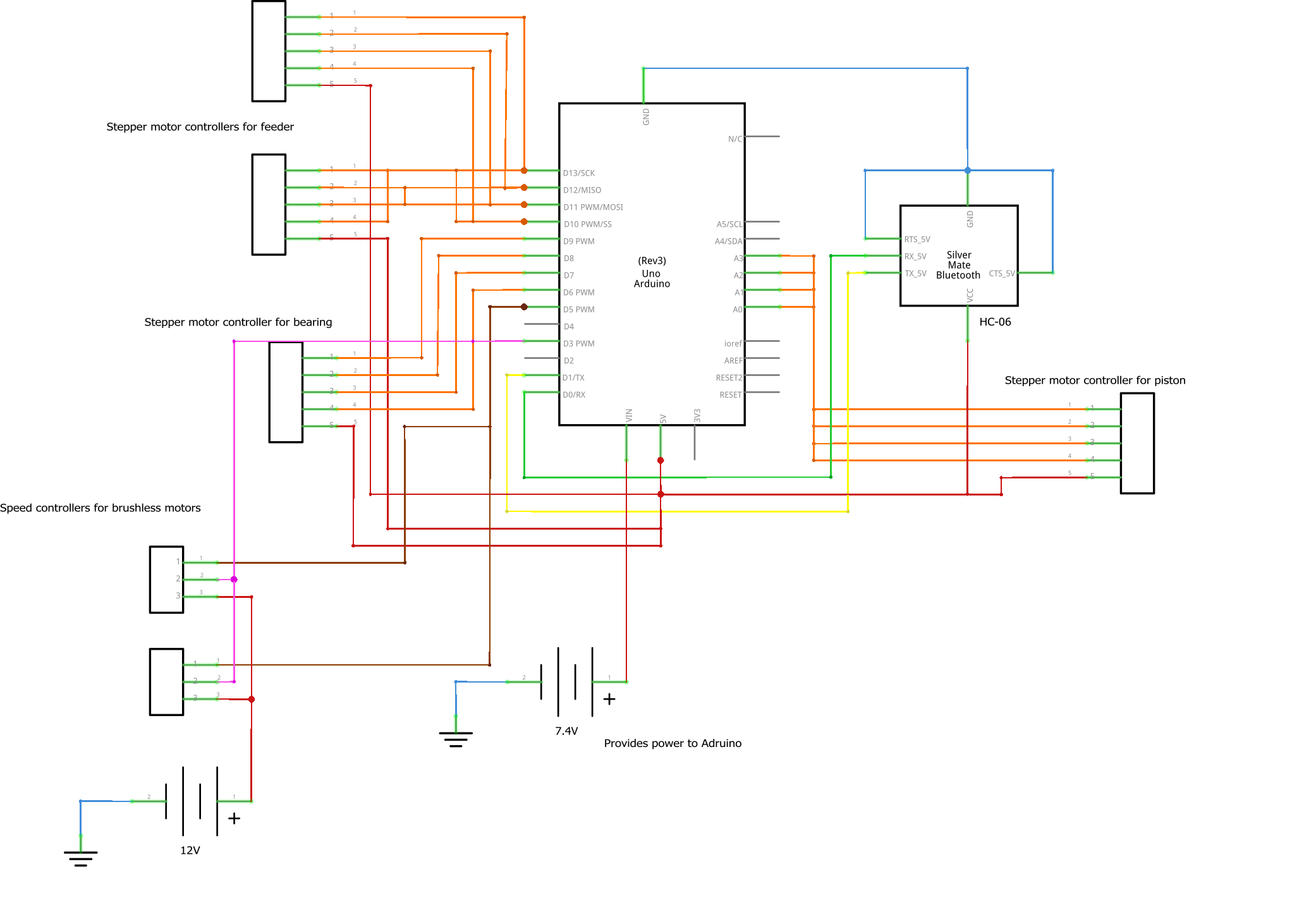

I was left solely in charge of the microcontroller part. I did consult my members for many parts, but I would say I did most of the work this part still. The choice of microcontroller was easy; it would be Arduino. There may be better choices, especially in terms of size. However, we felt that the Arduino was 'the' go to microcontroller that would be affordable while being open source. The microcontroller acts as the brain of the entire device. It receives the commands from the Android app via Bluetooth then it sends the required data to each port. We decided to use an HC-06 Bluetooth module since we already had one and that they were a very common module used for Bluetooth. The stepper motors were chosen purely because they were cheap and drew little power as we knew we wouldn't need stronger ones.

Figure 4. Adruino Schematic of BOSS

Assigned to: Allan Hieng

Mackenzie and I worked on this part since I had previous experience developing an Android app. My primary task was to make sure that we could connect the HC-06 module to the phone, while hers was to develop the app that would be used. I won't speak to much about the design of app since I believe it's a matter of taste and neither of us are experienced UI designers. The first task was to establish Bluetooth connection. This was surprisingly easy. It was a matter of opening a Bluetooth socket.

Assigned to: Mackenzie Wiens Allan Hieng

Despite the exhaustion and 2 car accidents that were involved in this project; I ended feeling very proud of what we had done. The judges at the presentation were very understanding and seemed interested in what we did. Considering we won something, I think we did pretty good. It was a good experience, and honestly it's kind of what a lot of students come into engineering thinking it would be like. Generally, I can think of many things that can improved. Our weakest point was the mechanical related stuff. Now for my honest thoughts as a badminton player. Trying to use this device as a shuttle feeder is not practical. It's extremely unnatural to move and react to it. I can understand why similar devices are not as popular besides the price. However, I think I'm being narrow minded. Many players grow and learn to watch the racket and react to the sound of the shuttle. This doesn't happen with a machine like this. So there are no cues when to move besides the scream of the motors, which leads me to feeling that it's unnatural. I think I could eventually get comfortable to this, but I think these kinds of tools can still be super effective at training novices who haven't begun to learn these subtle cues of when to move.